Sri Lanka earned US$ 930 million from the export of raw rubber and rubber products in 2023. Of that the major share, around US$900 million came from the export of rubber products.

Sri Lanka earned US$ 930 million from the export of raw rubber and rubber products in 2023. Of that the major share, around US$900 million came from the export of rubber products.

In the same year, Sri Lanka produced only 64 million kilograms of natural rubber compelling the industries to import over 30 million kilograms of natural rubber to the country. Foreign exchange outflow from the country for import of the shortfall in raw rubber requirement was around US$ 50 million. But the country has the potential to save this foreign exchange loss by becoming self-sufficient in its natural rubber.

The availability of natural rubber in the country will attract more investments to the natural rubber product manufacturing sector of the country further enhancing foreign exchange earnings and employment opportunities in the country.

Global scenario

The writer attended the International Rubber Conference 2024 (IRC 2024) in Indonesia and organised by the International Rubber Research and Development Board (IRRDB) in collaboration with the Indonesian Rubber Board. Key takeaways from the conference include that the current global demand and supply of natural rubber is 15.2 and 14.5 million metric tons respectively.

The global demand for natural rubber is expected to grow by 2.5% per year. However, production is predicted to grow only at the rate of 1.5%. The Director General of the International Rubber Study Group (IRSG) identified fluctuating rubber prices, new regulations such as EUDR (European Union Deforestation Regulations), Circular Leaf Spot Disease (CLSD) and diversifying rubber lands to alternate crops to negatively impact global natural rubber production.

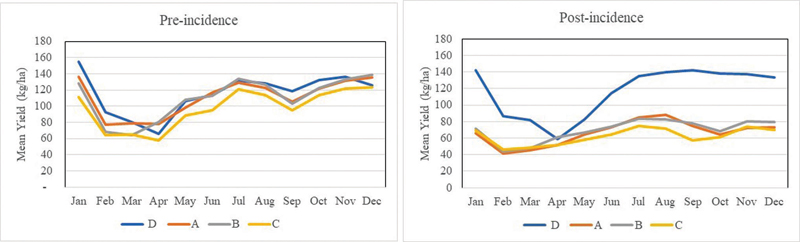

Figure 1. Mean monthly yield variation before and after CLSD impacting production. Except plantation D, others are located in the wet zone

The Secretary General of the Association of the Natural Rubber Producing Countries (ANRPC) said that the CLSD had spread widely across several rubber producing countries causing significant yield reduction up to 30 to 40%, in seriously affected areas.

EUDR will be effective from December 30, 2025 to ensure traceability and sustainability of rubber cultivations. With this regulation in force, legality of ownership of the cultivation and traceability in the supply chain will need to be set up. Deliberations highlighted the need for participants/producers to be incentivised to overcome their lack of interest to engage with such regulations.

Some factors highlighted above may increase the gap between the global natural rubber supply and demand and the indications are that the global NR prices will remain high in the future. Thus, the outlook for the global rubber industry is good.

Sri Lankan scenario

Sri Lanka’s natural rubber production has declined from 98.5 million kilograms in 2014 to 64.4 million kilograms in 2023. During the corresponding period the mature rubber extent in the country is reported to have come down from 106,000 to 85,000 hectares. Data also reveals that the mature rubber extent in the country has declined from 121 to 85 thousand hectares and the land productivity has increased from 629 to 835 kgs/ha/year from 2021 to 2022. Such drastic changes in industry performance within a year are not natural and needs investigating. Statistics need to be gathered and recorded accurately for policymakers and investors to arrive at informed-based decisions regarding the industry.

The national productivity level of rubber cultivation is generally lower than the potential in all rubber growing countries. In Sri Lanka it hovers around 800 to 900 kgs/ha/year while it is around 1,300 to 1,400 kgs/ha/year in countries such as India, Thailand and the Ivory Coast. One major reason for relatively high yields in certain countries is the more conducive soil and climatic conditions.

Generally, on flat land the adoption of agricultural practices are easy and soil degradation is less. Also, with less rainfall diseases are less and the number of tapping days is more. But in all countries, land productivity is less than the potential due to multiple reasons.

Having a lower number of plants than the recommended number of plants per unit land area, the productive stand becomes lower and lower due to increasing incidence of tapping panel dryness (a disorder which causes rubber trees to not produce rubber), not tapping the rubber trees due to lack of harvesters and interference of rain, poor quality of tapping due to the use of unskilled tappers, sub-optimal nutrient input, further reductions in heathy productive trees due to diseases such as the white root disease, wind and lightning damage are some of them. Most of the reasons identified above, that leads to low productivity is evident in traditional rubber growing areas in Sri Lanka negatively impacting national production.

New threats to rubber production

In 2019, rubber plantations in the country were affected by a new leaf disease. Around this period, rubber plantations in other countries too were affected by the same disease. This new disease is believed to be caused by one or more than one fungus. The severity of the disease is more in high rainfall areas. To-date there is no effective method developed by any country to control the disease. Hence, the disease prevails to date even under good agricultural practices.

The alarming situation is that in the wetter areas, two secondary/abnormal leaf falls have occurred during a year consecutively for the past three to four years. This scenario will seriously retard the health and growth vigour of rubber plants. It is definitely a threat to the future performance of rubber cultivations in traditional rubber growing wet regions. The other threat the rubber growers in the traditional rubber growing areas face is the high annual rainfall and the increased number of wet days per annum. The annual rainfall in the past four to five years has surpassed 5,000 mm with around 250 to 275 rainy days. This situation increases the incidence of pest and diseases incurring high costs to managements and lowering the quality of rubber clearings.

Weed management, fertiliser application and worker availability are also negatively impacted due to increased rains. For harvesting of mature rubber, rain guards have now become mandatory. Yet, the tapper and land productivities are compromised due to rain interference leading to lower rubber production and poor financial performance.

Intervention needed

The Government should be mindful of the consequences of the new leaf disease and the changes in climatic conditions on the rubber industry of the country. The political leadership should drive the State institutions and Departments to come out with suitable solutions to mitigate the adverse impact due to the above within a given time frame. The main strategies that may be considered by the authorities to prevent the ongoing downfall of the rubber industry in the country and to harness its potential benefits, is to develop methods to combat the new leaf disease through chemical or biological methods, breeding for resistance and escaping from disease vulnerable areas by moving rubber cultivations to non-traditional areas.

Controlling the disease with either chemicals or biological agents needs to include effective application methods considering the height of the trees and the terrain of rubber lands in affected areas. Promoting and facilitating rubber cultivation in the relatively dry non-traditional areas will have the advantages of soil less prone to degradation, a terrain conducive to implement agricultural practices and enhance worker productivity, more tapping days, less diseases and weed growth whist escaping from the threatening new leaf disease.

The political leadership and the State authorities have to be more serious about the threats the rubber industry is facing. By addressing these shortcomings the country will be rewarded with an increased dollar income.

The writer was a member of the Department of Plantation Management, Wayamba University and a former Director, Rubber Research Institute of Sri Lanka