Biomass boilers are often promoted as a renewable and carbon-neutral alternative to fossil fuel-based heating systems. However, their environmental impact depends on fuel type, combustion efficiency, and emission control systems. While biomass is considered more sustainable than coal or gas, it can still contribute to air pollution and other environmental issues if not appropriately managed.

Sri Lanka has seen growing interest in biomass boilers as an alternative to fossil fuels, particularly in industries like tea, rubber, and apparel manufacturing. However, the increasing demand for biomass fuel (mainly wood) raises concerns about deforestation, land degradation, and sustainability.

Sri Lanka has seen growing interest in biomass boilers as an alternative to fossil fuels, particularly in industries like tea, rubber, and apparel manufacturing. However, the increasing demand for biomass fuel (mainly wood) raises concerns about deforestation, land degradation, and sustainability.

Key Industries Using Biomass Boilers

*Tea Factories (Major consumers of fuelwood for drying tea).

*Rubber & Apparel Industries (Steam generation for processing).

*Small and Medium Enterprises (SMEs) (Brick kilns, bakeries, etc.).

*Polymer industries (Tire production, glove manufacturing)

*Food Industries (Chocolate, Meat production and processing)

*Hospitality (Hotels and restaurants)

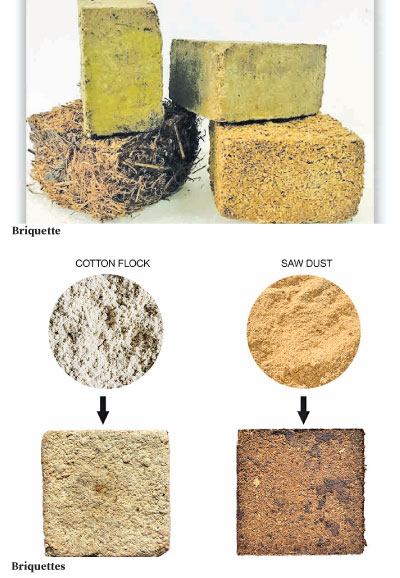

A reliable biomass supply chain is essential to ensure uninterrupted steam and hot water generation. Recognizing this need, researchers explored an innovative solution by developing fire briquettes from industrial waste materials—specifically, cotton flock discarded by glove manufacturers and sawdust from furniture and plywood production facilities.

A joint research initiative between the University of Sri Jayewardenepura and NSBM Green University focused on creating high-energy briquettes using various waste streams. The team utilised three primary waste materials: cotton flock (from glove manufacturing), Sawdust (from wood processing), and Corn cobs (from agricultural operations). These materials were combined with two natural binders: Palm oil processing sludge and recycled wastepaper.

The research strategically sourced all materials from local industries where they are typically considered waste products:

*Glove factories generate substantial cotton flock waste

*Agricultural operations and animal feed producers discard corn cobs

*Sawmills accumulate sawdust as a by-product

*Palm oil facilities produce sludge as a processing residue

This approach delivers dual benefits: it creates valuable fuel from discarded materials while addressing industrial waste management challenges. The project develops sustainable fuel sources by utilising locally available waste streams and contributes to more efficient waste utilisation within Sri Lanka’s industrial ecosystem.

Biomass briquettes offer numerous benefits as a sustainable fuel alternative, making them increasingly popular in industrial, commercial, and household applications. Below are the key advantages:

Biomass briquettes offer numerous advantages as a sustainable fuel source, beginning with their high energy efficiency. With a calorific value ranging between 3,800–5,000 kcal/kg, they outperform raw biomass and rival low-grade coal, while their low moisture content (10–15 percent) ensures cleaner, more efficient combustion with minimal smoke. Their uniform shape and density promote consistent burning in various applications, from industrial boilers to domestic stoves. Environmentally, briquettes help reduce deforestation by replacing traditional firewood and charcoal. At the same time, their use of agricultural and industrial waste materials makes them carbon-neutral when sustainably sourced, significantly lowering their carbon footprint. Additionally, they emit fewer pollutants like smoke, SO₂, and CO compared to coal and untreated biomass. As a waste management solution, briquettes effectively convert by-products such as sawdust, rice husks, and cotton waste into valuable fuel, reducing the burden on landfills and preventing the harmful open burning of organic waste. Economically, they present a cost-effective alternative to fossil fuels like furnace oil, LPG, and coal, with long-term savings and reduced reliance on imported energy sources due to local production capabilities. Their extended burning time decreases refuelling frequency, enhancing convenience. Beyond energy benefits, briquette production stimulates rural economies by creating income opportunities for farmers and small-scale entrepreneurs, fostering a circular economy through waste monetisation. Their versatility allows for diverse applications in industrial settings like tea factories and textile mills, cleaner domestic cooking solutions, and even power generation via biomass gasifiers. Finally, their compact, uniform shape simplifies storage and transportation, occupying less space than loose biomass, while their low moisture content prevents rotting and fungal growth, ensuring long-term usability. These advantages position biomass briquettes as a practical, eco-friendly, and economically viable fuel alternative.

Biomass briquettes offer numerous advantages as a sustainable fuel source, beginning with their high energy efficiency. With a calorific value ranging between 3,800–5,000 kcal/kg, they outperform raw biomass and rival low-grade coal, while their low moisture content (10–15 percent) ensures cleaner, more efficient combustion with minimal smoke. Their uniform shape and density promote consistent burning in various applications, from industrial boilers to domestic stoves. Environmentally, briquettes help reduce deforestation by replacing traditional firewood and charcoal. At the same time, their use of agricultural and industrial waste materials makes them carbon-neutral when sustainably sourced, significantly lowering their carbon footprint. Additionally, they emit fewer pollutants like smoke, SO₂, and CO compared to coal and untreated biomass. As a waste management solution, briquettes effectively convert by-products such as sawdust, rice husks, and cotton waste into valuable fuel, reducing the burden on landfills and preventing the harmful open burning of organic waste. Economically, they present a cost-effective alternative to fossil fuels like furnace oil, LPG, and coal, with long-term savings and reduced reliance on imported energy sources due to local production capabilities. Their extended burning time decreases refuelling frequency, enhancing convenience. Beyond energy benefits, briquette production stimulates rural economies by creating income opportunities for farmers and small-scale entrepreneurs, fostering a circular economy through waste monetisation. Their versatility allows for diverse applications in industrial settings like tea factories and textile mills, cleaner domestic cooking solutions, and even power generation via biomass gasifiers. Finally, their compact, uniform shape simplifies storage and transportation, occupying less space than loose biomass, while their low moisture content prevents rotting and fungal growth, ensuring long-term usability. These advantages position biomass briquettes as a practical, eco-friendly, and economically viable fuel alternative.

At the same time, produced briquettes were analysed to evaluate their properties and verify them as a fuel source. The shatter index, density, calorific value, flash point, and other necessary physical properties have been analysed to achieve that. Regarding calorific value, sawdust briquettes achieved values ranging from approximately 19.4 MJ/kg to 27.0 MJ/kg. These values are competitive with conventional biomass fuels, reflecting the high energy potential of sawdust combined with optimised binder ratios and compaction pressures. Higher binder content and compaction pressures yielded enhanced energy density, showcasing their importance in optimising fuel performance. The calorific value of cotton flock briquettes ranged from approximately 12.0 MJ/kg to 19.0 MJ/kg. While slightly lower than that of sawdust briquettes, the energy content remains sufficient for domestic and industrial applications. Both types of briquettes demonstrate significant potential for renewable energy applications, with sawdust offering slightly higher energy output and cotton flock contributing effectively to waste management and sustainability.

Cotton flocks are a primary feedstock, and when combined with palm oil sludge, they result in durable briquettes with a stable appearance. These briquettes leverage waste materials from the glove manufacturing industry, emphasising their role in waste valorisation and sustainable energy production. Their smooth surface and compact nature suggest good handling characteristics and efficient combustion potential, making them an eco-friendly alternative to traditional fuels. A structured approach involving testing, optimisation, industrial adoption, and policy support is essential to maximise the potential of cotton flock, sawdust, and corn cob briquettes. By addressing technical, logistical, and market barriers, Sri Lanka can transform these waste-derived briquettes into a sustainable, scalable fuel solution that benefits industries, the environment, and rural economies.

By: D.M.C. O. Ranaraja,

Faculty of Technology, University of Sri Jayewardenepura

Dr. N.A. Weerasekara,

Faculty of Technology, University of Sri Jayewardenepura

Dr. Udara S.P.R. Arachchige,

Faculty of Engineering, NSBM Green University